Member Stories

People make it happen! Not companies.

Interview partner:

Thema: Digitalisierung | Sprache: Englisch | Startup: Packwise

How three entrepreneurs revolutionize a traditional business niche

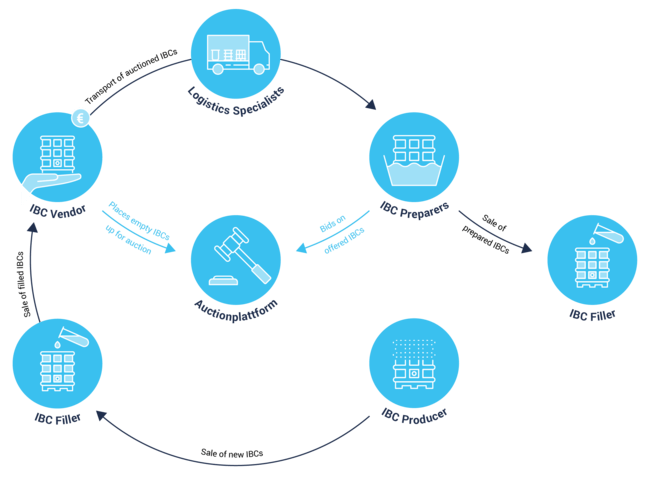

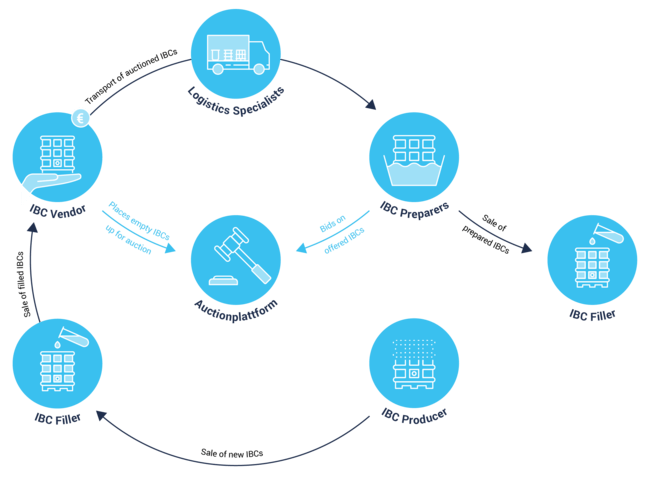

Starting your own business is no picnic—especially with three kids. Felix, Gesche and René aim to prove that it is not only possible, but also achievable in the very niche business of industrial containers. The three entrepreneurs‘ idea is simple and elegant: create a digital platform that connects businesses reselling used containers — mostly metal and plastic drums as well as IBCs (intermediate Bulk Containers) — to those who will use them again. They share their story and tell us how their platform actually works.

Q: How did you come up with the idea of Packwise?

Felix: I came up with a rudimentary version of this idea during my time as UK General Manager for an international packaging manufacturer. The company, and especially the site where I worked, was looking for ways to improve profitability. The company was producing new units and selling them to chemical companies that later filled them with their products and shipped them to their customers. I looked at improving the cost structure while also trying to figure out how to create new business models and start selling more efficiently. While I was able to implement the idea in the UK, the company struggled to roll it out Europe-wide.

Q: What was your idea to change this niche business?

Felix: We, the Packwise team, further developed this basic idea by looking for new ways to capture all the value that could be gained from addressing the whole packaging supply chain. We noticed that after using the content from IBC, these empty, dirty containers were usually just stored and wasted. There is an industry that is responsible for collecting these used containers in order to make them fit for use again, but it’s rather inefficient. As a result, the packaging gets sent around empty for unnecessarily large distances or it isn’t refurbished in the most efficient manner. We wanted to change that. That's when we realized that we needed to build our own startup.

Q: Why is this a big innovation?

Felix: We’re applying new digital communication tools to the world of industrial packaging. This project massively increases efficiency and therefore reduces resource consumption. Packwise is extremely valuable to our clients because our streamlined process reduces their workload. Without Packwise, selling packaging can be tedious and long waiting periods contribute to the process's overall inefficiency. With our platform, customers will have to spent significantly less time on the disposal of their empty packaging. Easy market access, overall inventory and logistics management, and easy access to relevant documents are Packwise's key USPs. By creating a transparent market, our customers will find their perfect match at a fair market price.

Packwise offers two complimentary products that cater to the same industries. First, Packwise Platform is best described as an ebay for used industrial packaging. Millions of metal and plastic drums as well as intermediate bulk containers (IBCs) are used as one-way-packaging to transport liquids between companies. Packwise Platform is a digital marketplace that makes sure these packaging types, after they have been used, will get to the industrial user that gets the most value out of them.

Luckily, we don't have to reinvent the wheel.

Every used industrial packaging container is already collected and refurbished by a competent business. Unfortunately, due to the lack of transparency and market inefficiency, the packaging gets sent around empty for unnecessarily long distances and/or inefficiently refurbished. As a digital platform, Packwise is perfectly suited to connect businesses to each other and make the process more efficient.

The second business model is called Packwise Loopz and aims at fundamentally changing the way industrial packaging is put to work. Instead of using drums and IBCs as a one way packaging, Packwise Loopz enables the companies that fill the containers to manage their packaging in cycles, or closed loops. As a web application, Packwise Loopz is built so responsively and automates so many processes that this complex market can easily be handled and monitored by one person. In doing so, Packwise even enables SMEs to participate in this sustainable and cost effective system. The combination of Packwise Platform and Loopz will allow clients to automatically check how to best manage their used packaging, whether that means selling it to another business close by or returning to their sender.

Q: What is your mission at Packwise?

Felix: Mission seems too big a word, but the members of the Packwise team enjoy combining all these powerful new tools—like cloud computing, big data analytics and mobile devices—to help a network of users organise the optimal solution for a complex issue. We love the fact that by saving money for customers, we're also enabling them to reduce the environmental impact of their packaging. It just feels right!

Q: I imagine that starting a business was not an easy decision?

Gesche: We started the company when our twins were almost a year old. Of course childcare was a big issue at first, but we found a very good kindergarten for our oldest son and decided that the girls would go there too. The good thing is that I didn’t have to quit my job or abandon anything all of the sudden because I was on maternal leave. For me it looked more like an opportunity than leaving something behind. Obviously not having a steady salary can make you wonder how you will make a living, but we decided to use our savings and give it a go. We decided that we would have a year to do our best and try to accomplish something.

René: I've always been self-employed, so it wasn't a difficult transition for me. I was convinced by the idea, so it was an easy decision to make.

Felix: I very much enjoyed working for both of my former employers. I learned a lot, gained a lot of experience, and developed a solid skill set. That said, I felt that there were a lot of promising opportunities I couldn't convince my employer to take. When Gesche and I started thinking about having our own business, we were raising our firstborn son and our newborn twins. We discussed this at length and consulted industry professionals. They thought our idea was very promising and we have a very supportive family close by, so we decided it was the right time to start Packwise. We were very lucky to meet René, who was eager to participate and confident he could turn the idea into a functioning web application.

Q: What are your main personal risks? What are the key challenges for Packwise's success?

Felix: When we discussed this as a team, we knew that if we would not try to execute our idea, someone else would. To be clear, we all have a reliable Plan B if Packwise does not succeed. With kids at home, the eagerness to take on risk needs to be kept well in check. Regarding our business model, we knew that we must focus on our customers needs while we develop Packwise. I was surprised to learn that most startups fail because they do not develop a product that meets the market's needs. That’s why we've involved multiple key users of our future products and services from the start. But despite very good feedback, you still don’t know for certain if you have the right solution until you start charging money. We aim to identify some of the “unknown unknowns” that pose a major risk to every startup sooner rather than later.

René: I agree with Felix. As a father of three, you cannot go kamikaze-like into the adventure. But the current demand for software developers gives me an amount of security that I will find additional projects if it becomes necessary.

Q: When did you join Impact Hub Dresden?

Gesche: I got into contact with Impact Hub Zürich in 2012, but only as an outsider attending conferences and talks etc. I strongly remember how excited everyone was about the newly opened Hub in Zürich and I loved the atmosphere there. I feel very lucky to have been one of the first members of Impact Hub Dresden. The timing here was just perfect for us.

René: Because my freelance work was remote work for companies based in western Germany, I've been working in coworking offices for a while. At the beginning 2017, I heard about the upcoming opening of Impact Hub Dresden. I knew Julian (one of the cofounders of the Hub) from events in his former coworking office. He showed me around and I was convinced right away to move here. I've been working here since April. Compared to other coworking offices, there is much more vibrant community life in the Hub.

Felix: I joined Impact Hub at the very beginning of its existence, when there were only a few chairs, some desks and internet access. I still had to buy coffee at the coffee shop around the corner, but it was a fun experience and I had everything I needed. It was the first time I worked in a coworking community, but the Impact Hub Team made the transition very easy and I've felt at home since day one.

Felix Weger

Gesche Weger

René Bernhardt

Q: How much has your business changed since then?

Felix: When we joined Impact Hub our idea wasn’t much more than a few drawings on paper. Since then a lot has changed. We've managed to create a solid business plan and find a perfectly well rounded full stack developer in René. Since René's joined the team of founders, he's programmed a prototype that has helped us collect highly valuable customer feedback and many LOIs. We've also managed to raise funding, develop our brand positioning and corporate design with the support of The Makers Club, a very supportive agency that is also based at Impact Hub.

We met The Makers Club members early on and we've profited a lot from their experience founding their startup, Stadt.Land.Netz, in addition to using their design and marketing services. Overall, we've developed a helpful network within the Dresdner startup community and we're very happy with the progress we've made so far.

Check out the interview part 2 and find out:

- What the Packwise team likes about Impact Hub Dresden

- Their learning and insights of running an early stage software startup

- What business/software tools they use

Du möchtest die nächste Story nicht verpassen?

Dann melde Dich für unsere HUBnews an.

Felix Weger

I am 34 years old and from Munich. I studied Economics with a focus on capital markets in Regensburg and Barcelona. After working for two years in a consultancy firm focused on Supply Chain Management, I became a general manager for a leading manufacturer of industrial packaging in Manchester and Dresden.

Contact: felix.weger(at)packwise.de

Gesche Weger

I started my career as a an Ecomonist at UBS in Zurich. I studied Economics at Universität Regensburg, Trinity College Dublin and Freie Universität Berlin. After finishing my masters, I spent a year studying and doing research at the Kiel Institute for the World Economy.

Contact: gesche.weger(at)packwise.de

René Bernhardt

I am 39 years old and I come from a village around 60km west of Dresden. Now I live together with my wife and our 3 kids on a farm in a little village just outside of Dresden. I studied computer science at the Technische Universität Dresden and Middlesex University London.

Contact: rene.bernhardt(at)packwise.de

Impact

Numbers & Facts

Impact

Number 12 | Sustainable Development Goals

The Packwise business model directly caters to the UN Goal of “Responsible Consumption and Reduction.” Packwise Loopz enables companies to organise their packaging in closed loops, promoting the benefits of the circular economy. It helps to extend the life cycle of packaging while reducing the down time during which packaging drums are sit empty in warehouses. Packwise Platform enables businesses to manage their loops and makes resource reuse as profitable as it is practical. As long as their packaging is fit for purpose, buyers will reuse it and, when they are done, recycle it. These are big changes inspired by a simple idea.

Numbers & Facts

Amount of CO2eq savings new vs. refurbished IBC

Amount of CO2eq savings new vs. refurbished steel drum

Number of units of IBCs being emptied in Germany

Number of units of drums being emptied in Germany

Length of time to start an auction on Packwise